People have been trying to make items of clothing waterproof for hundreds of years. Here in Mackay where its hot and humid when it rains, we don't really bother - we just use umbrellas. I imagine the original land owners, the aborigines, used large strips of paperbark stripped from the local Melalucca trees. In Asian countries woven hats or baskets were used to keep the rain off.

Indigenous peoples of other areas, such as the Amazon, used a milky substance extracted from rubber trees for this purpose. When European explorers came to the Americas in the sixteenth century, they observed the indigenous people using a crude procedure and rubber to waterproof items like footwear and capes, and these ideas were copied.

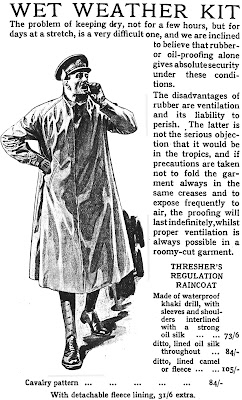

Meanwhile in Europe, where rubber trees did not grow, rain-wear was often made of wool, a natural insulator. G. Fox of London experimented with mixing twill and mohair and devised a rain coat called the ' Fox's Aquatic' in about 1820. Also used for water repellent clothing was Oilcloth, a close-woven cotton duck or linen cloth with a coating of boiled linseed oil. this was popular with early Australian Stockmen (known as a Driza bone), and sailors. Driza-Bone, originating from the phrase "dry as a bone", is a trade name for the company making full-length waterproof riding coats and apparel. The company was established in 1898, the trademark Driz-bone was registered in 1933 and is currently Australian owned and manufactures its products in Australia.

ilskins were also popular

with sailors and fishermen

, and referred to as a sou'wester.

By the 1880's rubber had arrived in Europe. Used extensively in foundation garments (and for pneumatic

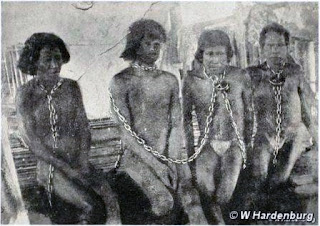

tyres for bicycles and motor cars), people also began with ways of waterproofing fabrics with rubber. Brazil and surrounding areas experienced

a 'rubber boom', which was not great for the indigenous

populations

, but did result in further exploration

of South America until the outbreak of WWI and

subsequent rubber plantations in Asia. The rubber boom and the associated need for a large workforce saw plantation owners, or 'rubber barons' round up Indians and force them to tap rubber out of the trees. Slavery and gross human rights abuses were widespread, and in some areas 90% of the Indian population was wiped out.

In Europe's cold, wet winters, the rubberised

clothing became hard and inflexible. In the early nineteenth century by Scottish chemist Charles Macintosh patented a process for making rubberised fabric by dissolving rubber in coal-tar naphtha, a by product of petroleum. The resultants liquid was brushed on fabric making it waterproof. The first Mackintosh coats were made in the family's textile factory, Charles Macintosh and Co. of Glasgow.

|

| Mackintosh Store,104 Mount St, Mayfair, London. |

Thomas Hancock of Manchester had also been experimenting with rubber coated fabrics since 1819, and in 1830 his company merged with that of Macintosh. Production of rubberised coats soon spread all over the UK, with the British Army, Railways and police forces all using rubberised coats.

These early coats still had problems with stiffness in the cold, and a tendency to melt and smell in hot weather. In 1843 Hancock patented a method for vulcanising rubber by cross-linking natural rubber with sulphur, which solved many of the problems. Charles Goodyear (1800–1860), generally credited as the first to come up with the basic concept of vulcanization, apparantly never fully understood the process as well as Hancock, and was awarded a patent in the United States three weeks after Hancock's British patent.

Throughout the 19th and 20th centuries, the Macintosh (also called Mackintosh) company continued to make waterproof clothing. In 1925 the company was taken over by Dunlop Rubber.

In 1849 the Americans developed a calendering process in which Macintosh's cloth was passed between heated rollers to make it more pliable and waterproof. In 1851, Box & Company introduced Aquascutum, a woolen fabric that was chemically treated to shed water, and designed a shower proof coat tailored with some style - The Prince of Wales, Edward VII soon had a range of informal and formal sporting clothes made by Aquascutum.

In the First World War soldiers in the trenches wore ankle length Aquascutum coats that had military design features with epaulets and pocket sand likewise Thomas Burberry created an all-weather trench coat (for soldiers in WWI - hence 'trench' coat) from treated twill cotton gabardine. After the war ended the coats spread in popularity, as they were much cooler than those made of Macintosh's fabric, and the trench coat remains a classic today.

In the 1920's Oil-skins again became popular, but using silk of fine cotton fabric instead of the heavier linen previously used. Here is Joan Crawford in an oilskin slicker in the 1927 silent film 'Twelve Miles Out' (with John Gilbert and Ernest Torrence), possibly the first rain coat in a movie.

|

| Twelve Miles Out, 1927 |

Polyvinyl chloride (PVC) was first created by German chemist Eugen Baumann in 1872, but it wasn't patented until 1913 when German, Friedrich Klatte invented a new method of the polymerization of vinyl chloride using sunlight. By the end of the 1920s plasticized polyvinyl chloride had been invented by Waldo Semon , and it was being used for shoe heels and golf balls. Soon it became popular for rain wear.

|

| , |

| The Hollywood Revue of 1929A “Singin’ in the Rain” featuring one of the earliest appearances of plastic macs in the cinema |

For some reason this makes me think of the 1970s and going to school in a see-through plastic rain coast. To me, this is the ultimate rainy day look.

As usual, more images on tumblr.

Deb xxx

In Holland we had poplin.gaberdine raincoats detachable under collar button off and on roomy lined hoods,, storm tabbed and back button split and tab, lined beige green black nay

ReplyDeleteI am looking for same and can you advice me

florienne lakes flyngduch@aol.com